Jit in toyota japan

Toyota Global Site | Just-in-Time

Toyota Motor Corporation Site introduces Just-in-Time. Striving to create outstanding earth-friendly products for sustainable growth, Toyota honors the laws, customs ...Just-in-time manufacturing - Wikipedia, …

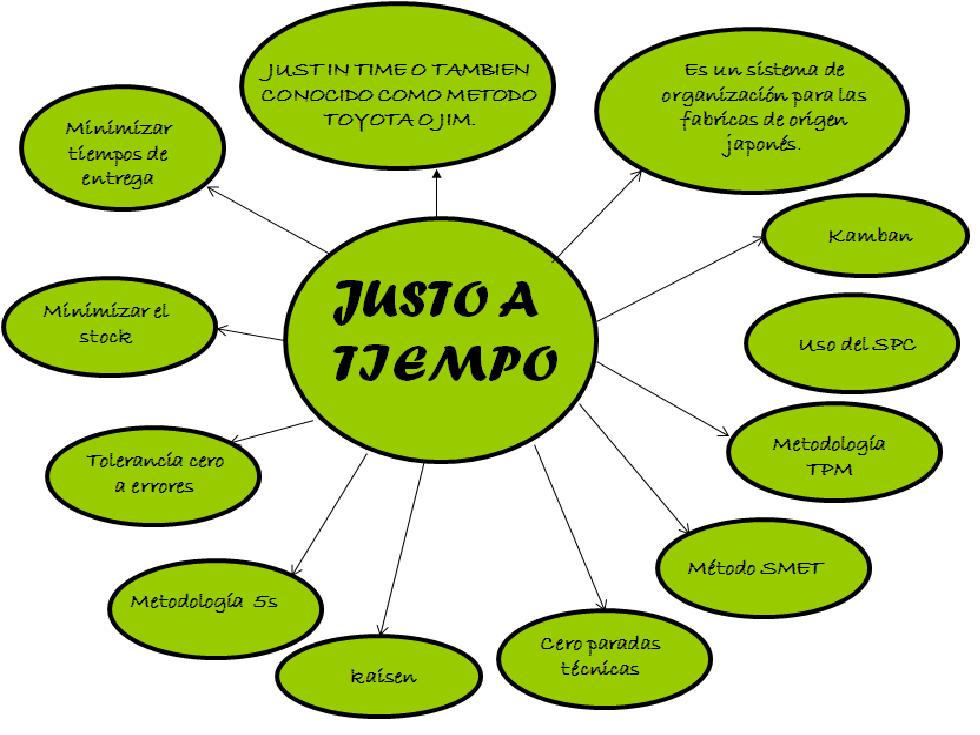

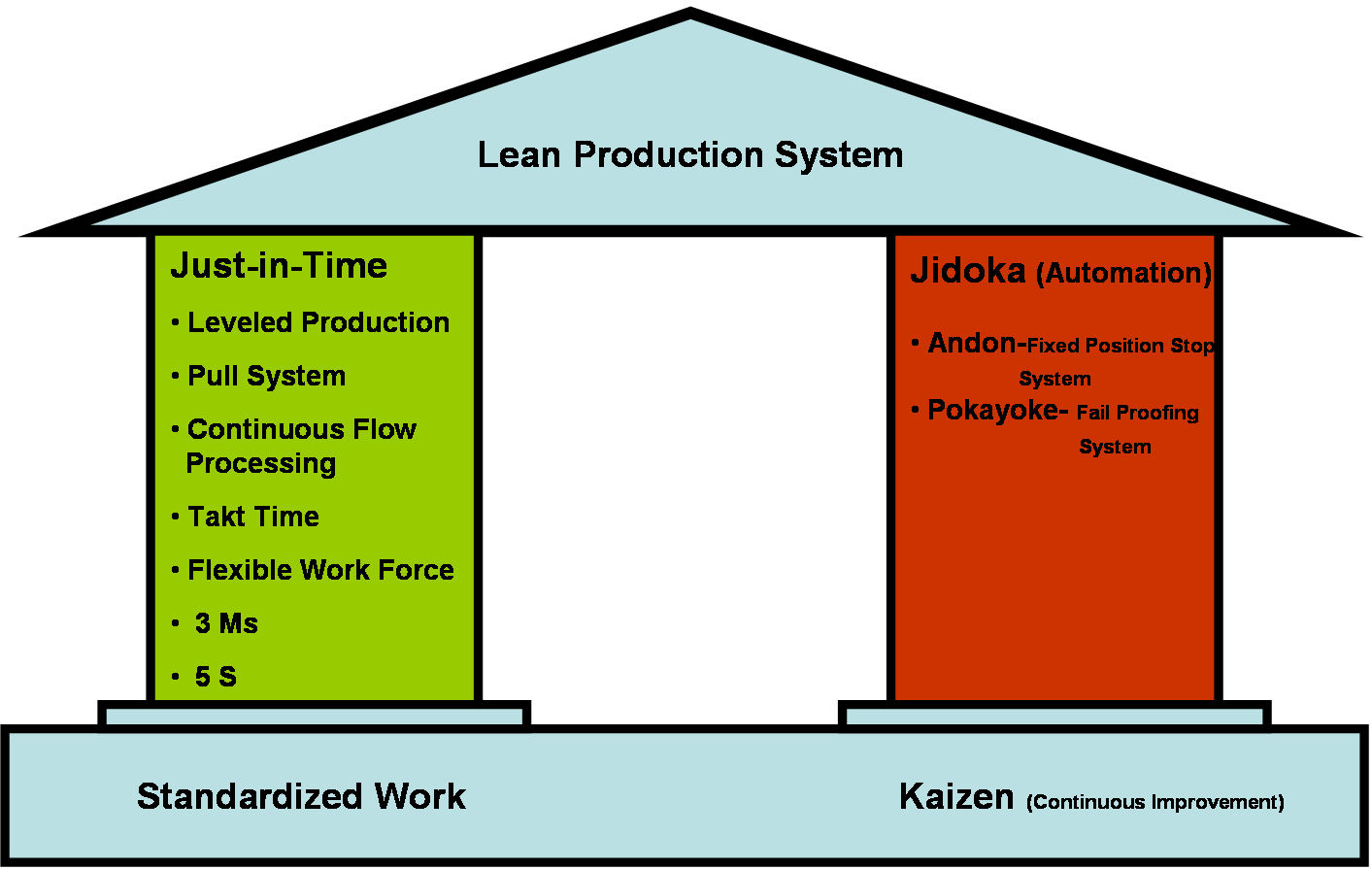

Just-in-time (JIT) manufacturing, also known as just-in-time production or the Toyota production system (TPS), is a methodology aimed primarily at reducing flow times ...Just-in-time | The Economist

06.07.2009 · When first developed in Japan in the 1970s, the idea of just-in-time (JIT) marked a radical new approach to the manufacturing process. It cut waste by ...Toyota Global Site | Production System

Toyota Motor Corporation Site introduces Production System. Striving to create outstanding earth-friendly products for sustainable growth, Toyota honors the laws ...JIT Just-in-Time manufacturing - Institute …

JIT Just-in-Time manufacturing ... Toyota realised that JIT would only be ... There are strong cultural aspects associated with the emergence of JIT in Japan.Lean Manufacturing Japan

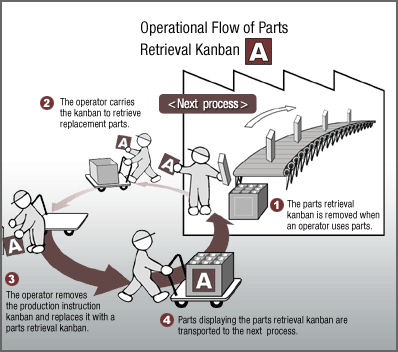

Broadcasting the latest Lean Manufacturing know-how from Japan for JIT, TPS, KAIZEN, KANBAN, 5S and more!Reducing Risk in The Automotive Supply …

Tsunami in Japan disrupted the JIT automotive supply chain. Suppliers shut down their facilities due to the natural disaster. OEM's need better risk managementJit In Toyota - SlideShare

20.09.2008 · Jit In Toyota 1. Chapter 11 Just-in-Time and Lean Systems JUST IN TIME AND LEAN SYSTEMS IN TOYOTA 2. Just-In-Time (JIT) ... Some plants in Japan …Just In Time :: Japanese Manufacturing …

Just-In-Time (JIT) is a Japanese manufacturing management method that was developed in the 1970’s. It was first adopted by Toyota manufacturing plants by Taiichi Ohno.Kanban Just-in Time at Toyota: …

Kanban Just-in Time at Toyota: Management Begins at the ... to introduce Toyota's own supplier companies to JIT. ... Management Begins at the Workplace by Japan ...

Source

Source

Source

Source

Source

Source

Source