Toyota lean thinking

Lean manufacturing - Wikipedia, the …

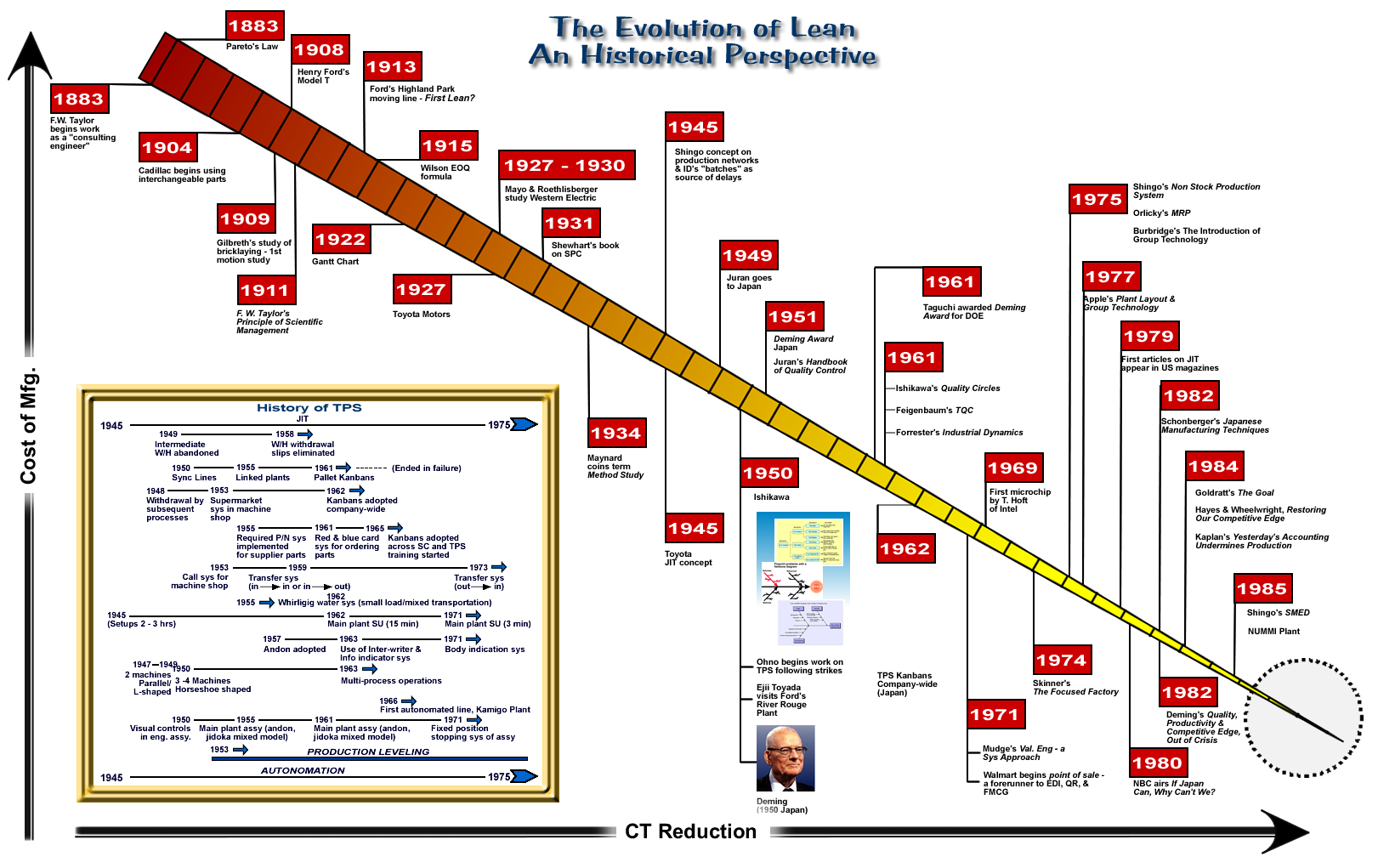

Lean manufacturing or lean production, often simply "lean", is a systematic method for the elimination of waste ("Muda") within a manufacturing system.A Brief History of Lean - Lean …

Although there are instances of rigorous process thinking in manufacturing all the way back to the Arsenal in Venice in the 1450s, the first person to truly integrate ...What is Lean? - Lean Manufacturing | …

The core idea is to maximize customer value while minimizing waste. Simply, lean means creating more value for customers with fewer resources. A lean organization ...Lean thinking - Wikipedia, the free …

Overview. Lean thinking was born out of studying the rise of Toyota Motor Company from a bankrupt Japanese automaker in the early 1950s to today’s dominant global ...Toyota Gal - How to implement "Lean …

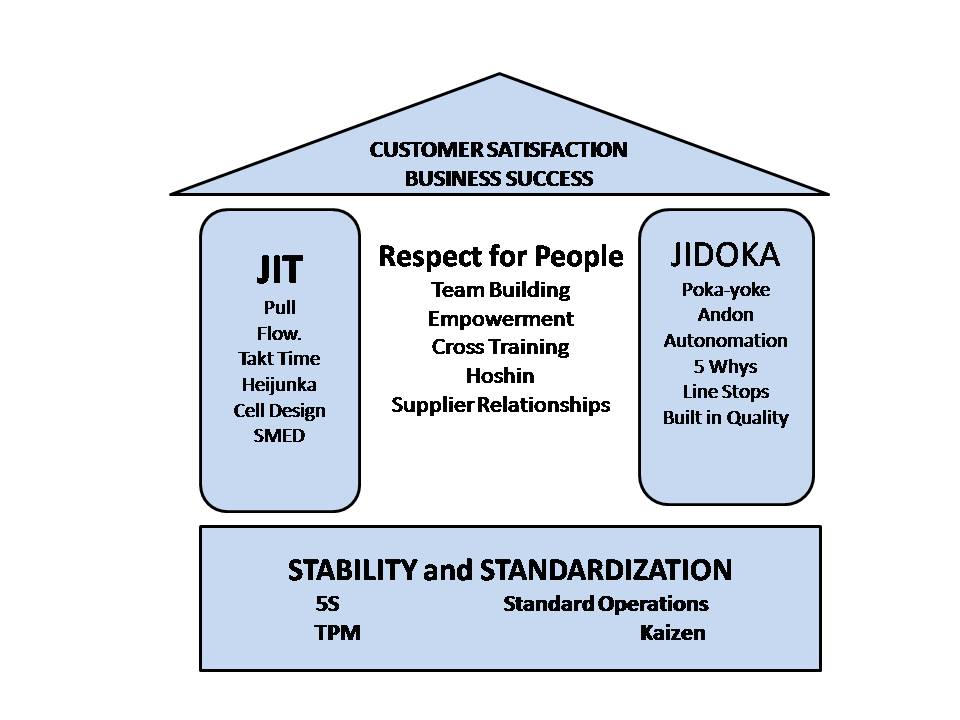

Lean, Lean Culture, Lean Implementation, Problem Solving, Strategy Deployment, Standardized Work, A3, Hoshin, Visual Management, Values, PrinciplesToyota Production System | TPS | …

Describes Toyota production system principles, how Eiji Toyoda and Taiicho Ohno impacted lean thinking and created lean management tools 5s, Kanban, kaizenLEAN THINKING - SlideShare

16.04.2010 · LEAN THINKING with Six Sigma Cutting Costs, Improving Quality, & Speeding Delivery b…Lean thinking - presentations - …

14.04.2011 · Lean thinking 1. Lean Thinking Banish Waste & Create Wealth in Your Corporation By: James P. Womack & Daniel Jones Book Report By: Billy ...Lean Thinking Training - Lean Six …

Singapore's leading Lean company offers Lean thinking course that covers the fundamental Lean principles, an overview of Lean tools and more.Shifting Definitions of "Lean …

What is "lean thinking?" Over the last 18 years we have seen four different definitions.

Source

Source

Source

Source

Source

Source

Source