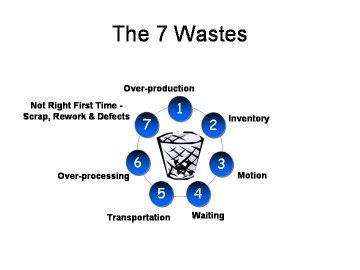

Toyota seven wastes

Muda (Japanese term) - Wikipedia, the …

Muda ???) is a ... Seven wastes One of the key steps ... They were identified by Toyota's Chief Engineer, Taiichi Ohno as part of the Toyota Production System ...What is seven wastes? - Definition …

What are the seven wastes? The seven wastes are categories of unproductive manufacturing practices identified by Taiichi Ohno, the father of the Toyota Production ...7 Wastes Muda Article on the Seven …

Seven Wastes by David McBride of EMS Consulting Group, an organization established to assist companies implement Lean and World Class Manufacturing programs.7 Wastes of Lean | iSixSigma

7 Wastes of Lean The 7 wastes are at the root of all unprofitable activity within your organization. The 7 wastes consist of: 1. Defects 2. OverproductionLean manufacturing - Wikipedia, the …

Lean manufacturing or lean production, ... TPS is renowned for its focus on reduction of the original Toyota seven wastes to improve overall customer value, ...The Toyota 7 Wastes Examples and …

We explain the Toyota Seven Wastes Examples and how each is related to each other.5S and 7 wastes according to Toyota …

and the seven types of wastes according to TOYOTA HOME Portals: 5S : Production: Lean Manufacturing: ... wastes are opportunities of gain the 5S help to harvest.Muda - The 7 Types of Waste - …

Muda — 7 types of Waste The 7 Deadly Wastes (muda) as defined by Taiicho Ohno (Toyota executive, 1912-1990) Defects; Overproduction of things not demanded by …Lean Manufacturing Glossary | 7 …

Lean Manufacturing Glossary | The Seven Wastes (7 Wastes) of Lean Manufacturing are Defined.Lean - Seven Wastes - NHS Institute …

Lean - Seven Wastes . ... Taiichi Ohno, who is credited with being the architect of the Toyota Production System, originally classified the 7 wastes.

Source

Source

Source

Source

Source

Source

Source