Concept of kanban used in toyota

Kanban - Wikipedia, the free …

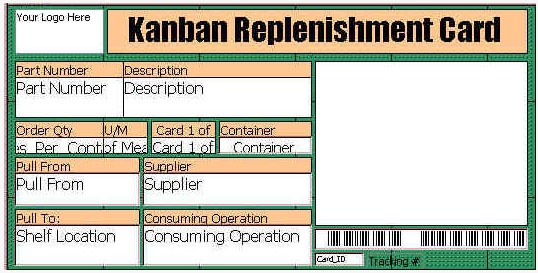

... an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. ... kanban is used for signalling demand to suppliers through email ...

Toyota Global Site | Just-in-Time

Toyota Motor Corporation Site introduces Just-in-Time. ... Because Toyota employed kanban signs for ... who promoted the idea of Just-in-Time, applied this concept, ...

What is Kanban? - LeanKit

What is Kanban? Learn the easy ... Short History of Kanban. In the late 1940s, Toyota found a better engineering process from an unlikely ... Toyota line-workers used ...

What is kanban ? And what are the …

Kanban one of many lean six sigma tools ... The concept behind the this lean manufacturing tool is ... used to replace defective parts and other uncertainties such ...

What is Kanban?

What is Kanban? Kanban is a way for ... Kanban is a concept related to lean and just-in-time ... Taiichi Ohno of Toyota applied the Kanban logic in their Toyota ...

Toyota Kanban concept MotoMachi …

28.03.2016 Toyota Kanban concept MotoMachi factory, Japan Chandan Datta. ... Learn How Kanban Systems are Used in a Lean Manufacturing …

What is kanban? - Definition from …

· Kanban is a visual symbol that’s used to trigger an action. The word kanban is ... Toyota introduced and refined the ... The concept of providing …

Toyota Global Site | Production System

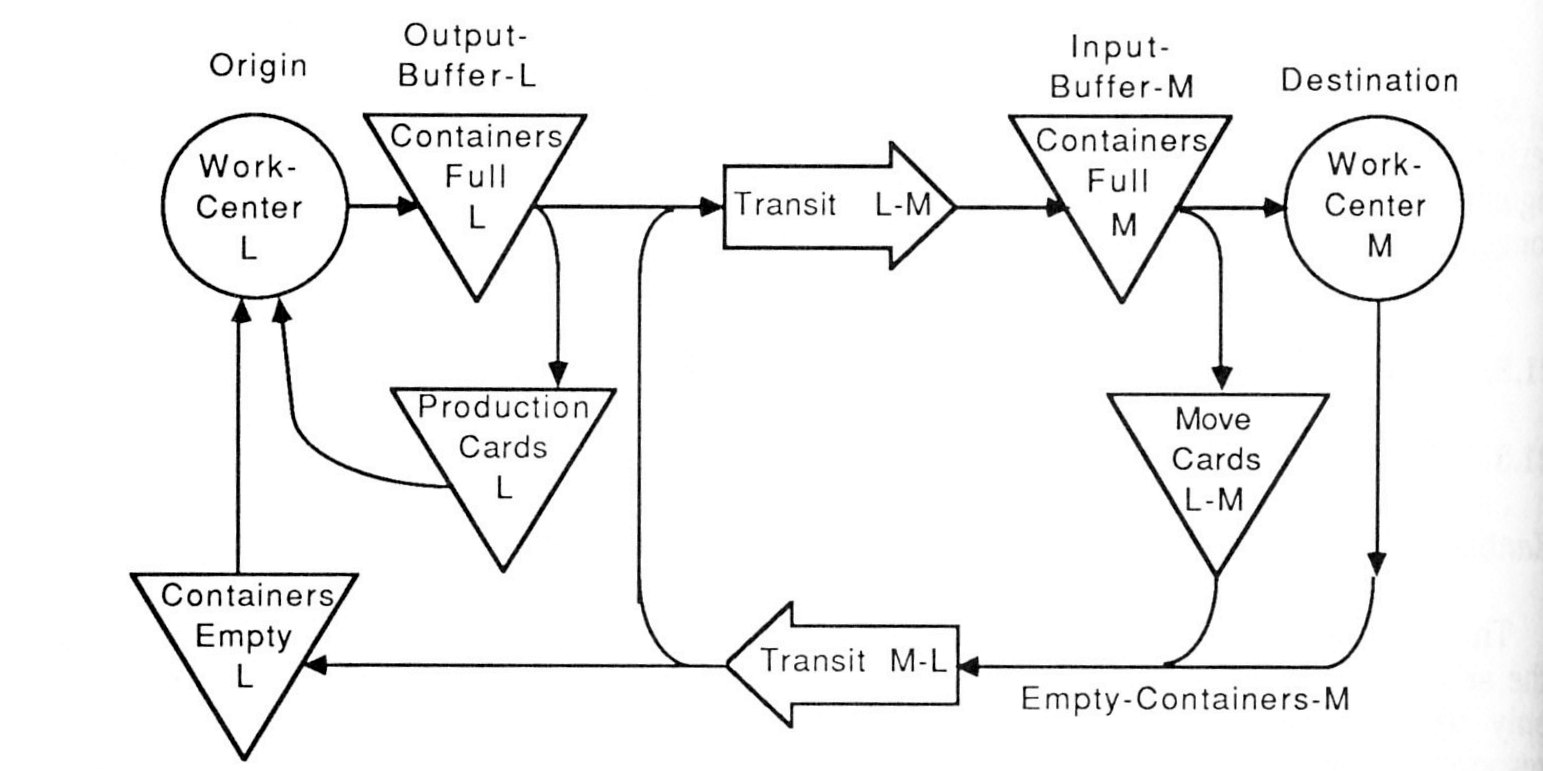

Toyota Motor Corporation Site ... The Toyota Production System ... The assembly line must replace the parts used by retrieving the same number of parts ...

KANBAN definition in Pull Systems | …

Kanban stands for Kan ... KanBan is often seen as a central element of “Lean” manufacturing and is probably the most widely used type of “Pull” signaling ...

A Brief Introduction to Kanban | The …

A brief introduction to kanban. ... Kanban is another framework used to implement ... Toyota optimized its engineering process by modeling it after how supermarkets ...

Source

Source

Source

Source

Source

Source

Source